NEWS

GENGYUAN

- The difference between galvanized sheet and stainless steel2023-08-16

- What are the characteristics of galvanized iron wire?2023-07-11

- Application of weathering steel plate in garden landscape2023-07-04

- Introduce the relevant knowledge of prepainted coil coating2023-07-07

- Why is 304 stainless steel tube so popular?2023-06-28

According to different production methods, it can be divided into hot -rolled pipes, cold -rolled pipes, cold pull tubes, and extruded tubes.

1, hot -rolled stainless steel seamless pipes are generally produced on automatic rolling pipe units. The solid tube blank was inspected and cleared the surface defects, and the required length was intercepted. They were attentive on the end surface of the perforated end of the pipe, and then sent to the heating furnace to heal, and perforated on the perforated machine. At the same time, the perforation is constantly rotating and moving forward. Under the action of rolls and tops, an empty cavity is gradually formed inside the tube. Send it to the automatic rolling machine and continue rolling. After the entire machine was thick, the whole machine was thick, and the diameter was determined to meet the specification requirements. It is a way to use a continuous pipe rolling unit to produce hot -rolled seamless steel pipes.

2. If you want to obtain a smaller size and a better quality, you must use the method of cold rolling, cold pull -out, or combination of the two. Cold rolling is usually carried out on a two -roller rolling machine. The steel pipe is rolled in the ring -shaped hole type composed of the turning round hole groove and the motionless cone top head. Cold drawing is usually performed on a single -chain or dual -chain cold pull machine of 0.5 to 100T.

3, the squeezing method is about to be heated in a closed squeezing cylinder, and the perforated rod is moved together with the extrusion rod to make the squeeze squeeze out of the smaller mold holes. This method can produce steel pipes with smaller diameter.

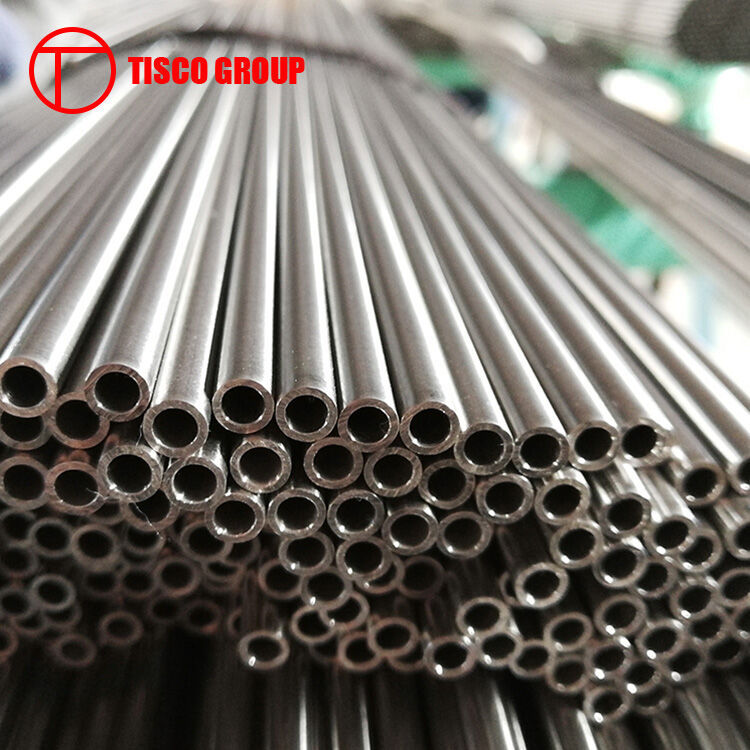

Such steel pipes can be divided into two types of stainless steel seamless steel pipes and stainless steel welded steel pipes (sewing pipes). According to different manufacturing processes, they can be divided into: hot rolling, squeezing, cold pulling and cold rolling. The shape of the section can be divided into round tubes and alien pipes. The circular steel pipes are widely used, but there are also some square, rectangular, semi -circular, hexagonal, equivalent triangles, octagonal and other alien stainless steel pipes.

The steel pipes that bears the fluid pressure must conduct hydraulic tests to test their pressure resistance and quality, and no leakage, wetting or swelling is qualified under the prescribed pressure. , Expansion test, flattening test.

Seamless stainless steel pipes are also called seamless tubes of stainless steel. It is made of a hair tube with a steel ingot or solid tube. The specifications of seamless steel pipes are represented by outer diameter*wall thickness millimeters.

Please give us a message